Discover how industrial SSDs protect data integrity in harsh environments. Learn about power loss protection, ECC technology, and critical features for industrial computing applications

Understanding the Importance of Data Integrity in Industrial Environments

The Critical Role of Data Integrity for Industrial Operations

In industrial computing, data integrity is the backbone of reliable operations. Whether controlling manufacturing lines, managing transportation systems, or monitoring critical infrastructure, ensuring that data remains accurate and uncorrupted is essential. Industrial SSDs are designed to safeguard this data, enabling seamless, real-time decision-making and operational continuity.

Modern industrial facilities depend on continuous data flow for process control, quality monitoring, and safety systems. A single corrupted sensor reading or lost control command can trigger production shutdowns, safety protocol activations, or even equipment damage. This makes data integrity not just a technical specification but a critical business requirement.

Challenges Faced in Harsh Environments (Temperature, Vibration, Dust)

Industrial environments are inherently challenging. Extreme temperatures ranging from -40°C in cold storage facilities to 85°C near industrial furnaces, persistent vibration from heavy machinery, dust, moisture, and electromagnetic interference can all threaten data integrity. These conditions accelerate hardware wear and increase the risk of data corruption, making it vital to select storage solutions specifically engineered for durability and resilience.

Consumer-grade SSDs designed for office environments typically fail within months when exposed to such conditions. Industrial settings experience power fluctuations up to 15 times more frequently than commercial buildings, with voltage spikes, surges, and sudden outages posing constant threats to data in transit.

Consequences of Data Corruption or Loss in Industrial Settings

Data corruption or loss can lead to costly downtime, safety hazards, compromised product quality, and regulatory non-compliance. Studies show industrial downtime costs average $260,000 per hour across manufacturing sectors. In critical applications, even minor data errors can cascade into significant operational failures, emphasizing the importance of robust data protection mechanisms in industrial SSDs.

Beyond financial losses, corrupted data in medical device manufacturing can lead to FDA compliance violations. In transportation control systems, data errors could compromise passenger safety. The reputational damage and potential legal liability make investing in proper data protection essential rather than optional.

Key Features of Industrial SSDs that Ensure Data Integrity

Robust Construction and Rugged Design for Durability

Industrial SSDs feature ruggedized enclosures, shock and vibration resistance, and wide operating temperature ranges. This construction ensures they withstand the physical stresses typical of industrial environments, maintaining data integrity over extended periods.

Key durability features include:

- Conformal coating protection against moisture and corrosive atmospheres

- Reinforced solder joints to withstand constant vibration

- Sealed enclosures preventing dust and particle ingress

- Extended temperature certification from -40°C to 85°C (or -55°C to 125°C for military applications)

Advanced Error Correction Technologies (ECC)

ECC technology detects and corrects data errors on the fly. Industrial SSDs employ sophisticated error correction algorithms like LDPC (Low-Density Parity-Check) and BCH codes, which significantly reduce the risk of silent data corruption and extend device lifespan.

Modern ECC implementations can correct bit error rates up to 10^-7, effectively catching errors introduced by electromagnetic interference, cosmic ray strikes, or natural NAND flash deterioration. This continuous error correction works invisibly in the background, ensuring data accuracy without impacting system performance.

Power Loss Protection Mechanisms

Unexpected power outages can jeopardize data integrity. Industrial SSDs incorporate power loss protection features such as supercapacitors or backup power circuitry to preserve data during sudden shutdowns, preventing corruption and data loss.

When voltage drops are detected within microseconds, the PLP system provides 250ms to several seconds of emergency power, allowing the SSD controller to flush all cached data to non-volatile NAND flash and complete any in-progress write operations. This ensures zero data loss even during the most abrupt power failures.

Firmware Reliability and Validation

Reliable firmware ensures consistent performance and security. Industrial SSDs undergo rigorous validation processes, including secure boot and firmware integrity checks, to prevent malicious attacks and firmware-related errors that could compromise data.

For applications in critical infrastructure, defense, or medical sectors, validated firmware with cryptographic signatures ensures only authorized code executes on the device. This prevents both intentional attacks and accidental corruption from compromising system integrity.

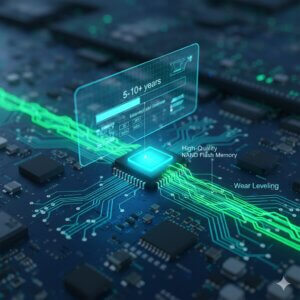

High-Quality NAND Flash Memory and Wear Leveling

Using industrial-grade NAND flash memory with advanced wear leveling algorithms ensures consistent performance and prolongs SSD lifespan. This is crucial for maintaining data integrity over millions of write cycles.

Dynamic wear leveling monitors every memory block’s program/erase cycle count, redistributing writes to ensure even the most static data periodically moves to fresher blocks. Combined with overprovisioning (7-28% hidden reserve capacity), this extends operational lifespan from 1-2 years to 5-10+ years in 24/7 industrial environments.

Power Loss Protection in Industrial SSDs

Explanation of Power Loss Events and Their Impact on Data

Power loss events occur unexpectedly due to outages, surges, or system faults. Without protection, these events can interrupt write processes, leading to incomplete data writes, corrupted files, or even device failure. In industrial settings where systems operate unmanned or in remote locations, power loss protection becomes critical for preventing data loss that would require manual intervention and extended downtime.

Types of Power Loss Protection (Supercapacitors, Backup Power)

| Type | Function |

|---|---|

| Supercapacitors | Store energy to complete ongoing write operations during outages |

| Backup Power Supply | Provide continuous power to SSDs, ensuring safe data write finalization |

Both mechanisms monitor power rails continuously and activate instantly when voltage drops are detected, providing the critical seconds needed to preserve data integrity.

How Power Loss Protection Preserves Data During Unexpected Outages

By supplying immediate energy, power loss protection mechanisms allow SSDs to flush cached data to non-volatile memory safely. This process prevents data corruption and maintains the integrity of critical information. The PLP system executes a carefully orchestrated emergency protocol: stopping new write commands, flushing DRAM cache contents, updating metadata tables, and placing the drive in a protected state until power restoration.

Benefits for Industrial Applications with Critical Uptime Requirements

Power loss protection minimizes downtime and data recovery efforts, ensuring industrial systems operate smoothly even during power disturbances. This reliability is vital for applications like factory automation, transportation control systems, and energy management where unexpected shutdowns could trigger safety protocols or halt production lines worth millions per hour of downtime.

Error Correction Code (ECC) Technology and Data Reliability

Overview of ECC and Its Function in Detecting and Correcting Errors

ECC algorithms analyze stored data, identify discrepancies, and correct errors before they impact operations. This proactive approach ensures data accuracy and system stability. Unlike simple parity checks, modern ECC schemes can detect multi-bit errors and correct them in real-time, creating an invisible safety net that maintains data integrity without user intervention.

Types of ECC Used in Industrial SSDs (LDPC, BCH)

| ECC Type | Description |

|---|---|

| LDPC | High-level correction for demanding environments, prolongs SSD endurance |

| BCH | Suitable for moderate error rates, commonly used in embedded systems |

LDPC (Low-Density Parity-Check) represents the current industry standard, offering superior error correction capability essential for harsh industrial environments. BCH (Bose-Chaudhuri-Hocquenghem) codes provide reliable correction for applications with moderate error rates and lower complexity requirements.

Impact of ECC on Prolonging SSD Lifespan and Maintaining Data Accuracy

ECC reduces the accumulation of uncorrected errors, preventing silent data corruption that can go unnoticed. This prolongs SSD lifespan and ensures data remains trustworthy over time. By correcting errors before bad blocks develop, ECC effectively doubles or triples the usable lifespan of industrial SSDs compared to consumer drives without advanced error correction.

ECC’s Role in Preventing Silent Data Corruption

Silent data corruption occurs without immediate detection, risking system failures. ECC’s error detection and correction capabilities act as a safeguard, alerting systems to issues before they escalate. This is particularly critical in data logging applications or quality control systems where corrupted historical data might not be discovered until long after the error occurred, making correction impossible without proper ECC protection.

Additional Critical Features for Industrial SSD Data Integrity

Firmware Validation and Secure Boot Processes

Secure firmware validation prevents malicious code execution and firmware corruption, maintaining the integrity and security of the SSD. Industrial SSDs implement cryptographic verification that checks firmware signatures during boot, ensuring only authorized code executes. This protects against both cyber attacks and accidental corruption that could compromise data integrity.

Overprovisioning and Wear Leveling Strategies

Overprovisioning allocates extra storage (typically 7-28% of total capacity) to distribute write and erase cycles evenly, reducing wear and maintaining data reliability. This hidden reserve space provides replacement blocks when others wear out, enables efficient garbage collection, and maintains consistent performance even as the drive approaches capacity limits.

Temperature Management and Thermal Throttling

Effective thermal management prevents overheating, which can degrade NAND flash and cause errors, ensuring consistent data integrity. Industrial SSDs employ intelligent thermal throttling that maintains minimum guaranteed performance levels rather than aggressively reducing speed, ensuring control systems remain stable even under thermal stress.

Compatibility with Industrial Computing Standards and Certifications

Industrial SSDs often meet standards like IEC, UL, or RoHS, ensuring compatibility and reliability in various industrial applications. Additional certifications may include:

- MIL-STD-810G: Military-grade environmental testing

- EN 50155: Railway applications standard

- IEC 61508: Functional safety for industrial automation

- CE/FCC: Electromagnetic compatibility certification

Monitoring and Management Tools for Ongoing Health Assessment

Built-in diagnostics and management software enable proactive monitoring of SSD health, predicting failures before they occur and ensuring continuous data protection. SMART (Self-Monitoring, Analysis and Reporting Technology) attributes provide detailed health metrics including remaining lifespan predictions, bad block counts, temperature history, and power cycle tracking, enabling predictive maintenance strategies.

Selecting the Right Industrial SSD for Your Application

Factors to Consider: Environment, Capacity, Performance, and Reliability

Assess environmental conditions, required storage capacity, performance needs, and reliability standards to choose an SSD tailored to your application. Document actual operating conditions including temperature ranges with safety margins, vibration levels, power stability, and expected workload patterns. This enables proper specification matching and prevents costly mismatches.

Key selection criteria:

- Operating temperature range: Match to deployment environment with 10-15°C safety margin

- Endurance requirements: Calculate daily write volume and match to DWPD ratings

- Performance needs: Distinguish between sequential vs. random workload characteristics

- Form factor compatibility: Ensure physical and electrical compatibility with existing systems

Importance of Certifications and Compliance Standards

Verify that the SSD complies with relevant industrial standards to ensure durability, safety, and interoperability. Certifications provide independent validation that drives meet specified environmental, safety, and performance requirements. For regulated industries like medical devices or railway systems, proper certification isn’t optional—it’s mandatory for legal compliance.

Evaluating Vendor Support and Warranty Services

Choose vendors offering comprehensive support, firmware updates, and warranties to safeguard your investment and ensure ongoing data integrity. Critical evaluation factors include:

- Long-term availability: Minimum 5-7 year supply guarantees with locked Bill of Materials

- Technical support: Responsive engineering support and application assistance

- Firmware customization: Ability to adapt firmware for specific requirements

- Warranty coverage: Clear RMA processes and reasonable mean time to replacement

- Reference customers: Proven track record in your specific industry vertical

Case Studies/Examples of Industrial SSD Deployments Ensuring Data Integrity

| Application Area | SSD Role and Benefits |

|---|---|

| Manufacturing Automation | Maintains real-time control data with ECC and PLP for PLC and SCADA systems |

| Transportation Systems | Withstands vibration and temperature fluctuations in railway signaling and traffic control |

| Energy Infrastructure | Secure, validated SSDs safeguard critical operational data in smart grid systems |

| Medical Equipment | FDA-compliant storage ensures accurate diagnostic imaging and patient monitoring data |

| Military & Aerospace | Extreme-rated SSDs operate reliably in -55°C to 125°C conditions with high shock resistance |

Conclusion

Recap of Essential Features and Technologies

Industrial SSDs equipped with robust construction, advanced ECC, power loss protection, and reliable firmware are vital for maintaining data integrity in harsh environments. These features work together synergistically: rugged hardware withstands physical stress, PLP protects against power disturbances, ECC corrects data errors, and validated firmware ensures security—creating comprehensive data protection that consumer or enterprise SSDs cannot match.

The Strategic Importance of Choosing Industrial SSDs with Robust Data Protection

Investing in industrial SSDs with comprehensive data integrity features ensures operational continuity, safety, and compliance, ultimately reducing downtime and maintenance costs. While industrial SSDs cost 2-4x more upfront than consumer alternatives, their extended 5-10 year lifespan, zero unplanned downtime risk, and avoided emergency replacement costs deliver superior total cost of ownership (TCO) for mission-critical applications.

Consider that a single hour of industrial downtime averages $260,000 in losses. An industrial SSD costing $500 versus a $150 consumer drive that fails after 18 months represents not just better value but essential risk mitigation. Factor in avoided downtime, eliminated data recovery costs, and reduced maintenance overhead—the ROI becomes undeniable.

Future Trends in Industrial SSD Technology for Enhanced Data Security

Emerging innovations like AI-driven health monitoring, enhanced encryption, and even more resilient hardware designs promise to further elevate data security and reliability in industrial computing. Predictive analytics will anticipate failures weeks in advance, quantum-resistant encryption will protect long-term data security, and emerging storage class memory technologies will bridge the performance gap between DRAM and NAND flash.

As edge computing and Industry 4.0 initiatives expand, industrial SSDs will evolve to support AI inference workloads, 5G connectivity requirements, and increasingly sophisticated cybersecurity demands. By understanding and prioritizing these features today, procurement professionals can make informed decisions ensuring their industrial computing applications remain reliable, secure, and efficient for years to come.

Frequently Asked Questions (FAQ)

Q1: What is Power Loss Protection (PLP) in industrial SSDs and why do I need it?

Power Loss Protection (PLP) is a hardware-based safety mechanism using supercapacitors or backup power circuits that preserve data during unexpected power failures. When voltage drops are detected, PLP provides 250ms+ of emergency power to flush cached data to NAND flash, ensuring zero data loss. It’s essential for industrial applications where sudden power outages occur 15 times more frequently than in commercial settings, preventing data corruption that could cause costly downtime averaging $260,000 per hour.

Q2: How do industrial SSDs differ from consumer or enterprise SSDs?

Industrial SSDs offer three critical advantages: wider temperature ranges (-40°C to 85°C vs. 0°C to 70°C), standard Power Loss Protection (optional or absent in consumer/enterprise drives), and higher endurance (3-10+ DWPD vs. 0.3-1 DWPD). They also feature conformal coating for moisture protection, 5-7 year supply guarantees with locked BOMs, and firmware customization options. While costing 2-4x more upfront, industrial SSDs last 5-10+ years in 24/7 operations versus 1-2 years for consumer drives, delivering superior total cost of ownership.

Q3: How long do industrial SSDs typically last in continuous operation?

Industrial SSDs designed for 24/7 operation typically last 5-10+ years when properly specified, compared to 1-2 years for consumer SSDs in the same conditions. Lifespan depends on workload intensity (DWPD), operating temperature, and environmental stress. Advanced wear leveling and overprovisioning (7-28% hidden capacity) extend endurance by redistributing write cycles evenly. For example, a 1TB industrial SSD rated at 5 DWPD can sustain 5TB daily writes for 5 years—approximately 9,125 TBW (Total Bytes Written) total lifetime.

Q4: What certifications should I look for when selecting industrial SSDs?

Key certifications validate reliability and compliance: MIL-STD-810G for military-grade environmental durability, EN 50155 for railway applications, IEC 61508 for functional safety in industrial automation, and CE/UL/RoHS for basic safety and environmental compliance. For regulated industries, verify FDA compliance (medical devices) or ATEX ratings (explosive atmospheres). These certifications provide independent validation that SSDs meet specified performance and safety standards, essential for legal compliance in critical infrastructure applications.

Industrial computing demands industrial-grade storage. Choose wisely to protect your operations, your data, and your investment.

Contact Dellwa today to protect your industrial operations with certified industrial SSDs.