Looking at industrial memory module from the chip level

What are the key differences between industrial modules and commercial standard memory? Why did it cause such a significant impact? DRAM IC chip level is the first issue that needs to be understood…

As the world enters the 5G era, it also means that the vision of intelligent Internet of Things (AIoT). Like self-driving cars and Internet of Vehicles (IoV) applications will accelerate.

In response to the ever-increasing demand for data storage, transmission and computing in the future, industrial applications such as data centers, servers and even edge computing devices are repeatedly expected to replace traditional mobile devices and become the most critical growth driver for the memory industry.

The role of real-time data is becoming more and more important, and the responsibilities assigned to memory are becoming more and more important, and its requirements for durability and reliability are increasing. Misuse of commercial standard products in an industrial application environment may result in a high failure rate and failure rate of the memory, increase the risk of loss and damage of important data, and even cause unexpected system shutdown.

As for the key differences between industrial and commercial standard memory module. They will cause such a significant impact, DRAM IC chip level is the first issue to be understood.

Identify DRAM IC chip grade from appearance

Generally speaking, DRAM ICs can be divided into four grades, with quality in descending order: Major original particles, eTT, uTT, and downgrade.

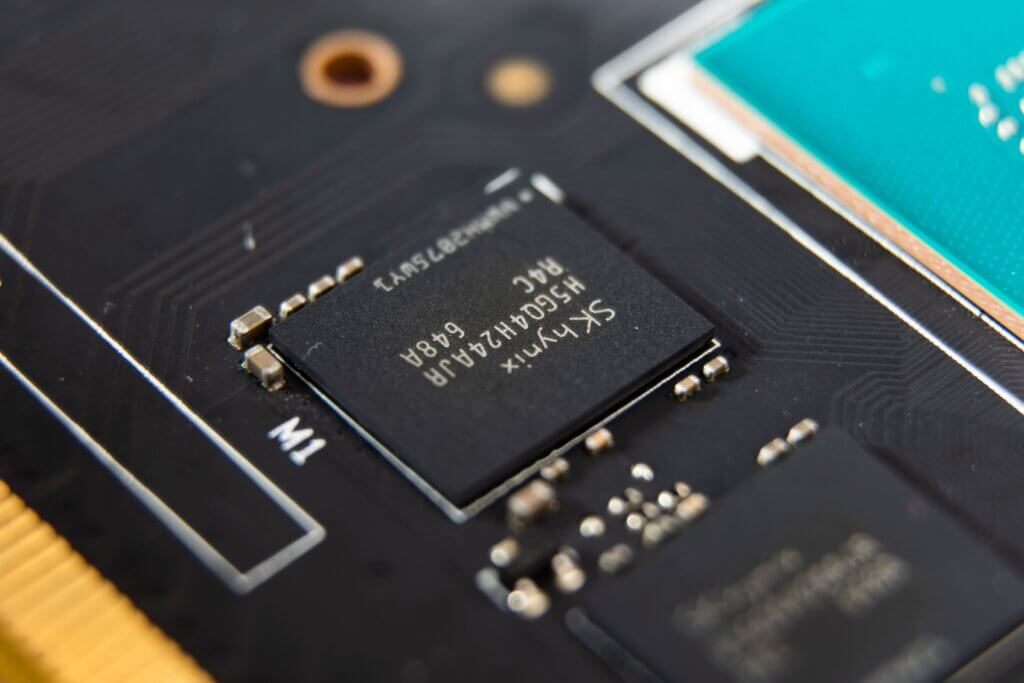

1. Major original particles: Produced by memory manufacturers, select the best quality wafers, and pass the original factory complete test procedures. The IC will print the manufacturer’s trademarks such as: Samsung, Micron, SK Hynix, etc. Users can clearly identify the specifications and manufacturers of the IC, and enjoy warranty services.

2. eTT (Effectively tested DRAM): DRAM particles that have only undergone a certain effectiveness test, but have not been fully tested. The quality is lower than the original Major-grade DRAM. It is mainly purchased by downstream memory module manufacturers from the original manufacturer and then stamped with their own trademark logo for external sales.

3. uTT (Untested DRAM): Refers to DRAM particles that have not been tested after packaging. The quality is usually doubtful. It is also purchased by downstream memory module manufacturers and stamped with their own trademark logo for external sales.

4. Downgrade: It is made of wafers and pellets with poor yield and mixed with pellets that cannot meet Major and eTT test standards. This level of IC often has serious compatibility and high defect rates, and cannot meet general quality requirements.

DRAM IC: The decisive element of memory reliability

At present, commercial standard memory on the market mostly uses eTT, uTT and even secondary ICs, which are often used in price-oriented consumer products or low-end applications.

These three levels of ICs are processed after subsequent processing, the downstream memory module manufacturer’s trademarks are stamped. Therefore, it is difficult for general users to identify which of eTT, uTT, or substandard products they use from their appearance. Increasing the risk of using inferior products.

As for high-end industrial control market, server and data center applications, because it is difficult to bear the risk of system downtime caused by unstable memory quality. It mostly use industrial-grade memory modules made of Major grade original DRAM ICs and the IC is stamped with the original manufacturer’s trademark.

Even though the cost is higher, the highest product quality and reliability can be obtained. On the other hand, even if the product is abnormal, it can be covered by warranty clauses such as original factory maintenance, return and exchange, or sent back to the original factory for failure analysis to find out the actual cause of the problem, so as to avoid the same problem from recurring.

Value-added technology, rigorous testing, and Fixed B.O.M. Industrial-grade memory Module applications are indispensable

Industrial memory is used in diverse applications, or is often used in complex and harsh environments. It not only needs to withstand extreme temperature changes, but also faces external environmental challenges. Such as humidity, dust, environmental pollution, vibration and shock.

Therefore, the application of value-added technology for industrial-grade memory module has become one of the biggest differences between them. And general-purpose commercial memory module products, such as wide temperature range (-40 ~ +85°C), 30μ gold plating. And Conformal coating (Conformal Coating), anti-vulcanization and underfill technology, thereby effectively improving product reliability and durability.

On the other hand, in addition to the complete test procedures for DRAM ICs, industrial-grade memory module also need to pass a series of stringent tests or certifications to ensure product performance and stability.

Common tests such as high and low temperature tests, Temperature cycle test, switch machine cycle test, vibration and shock test and continuous reliability test, etc., can all be used as the judgment standard of whether the memory module meets the industrial level.

Finally, consumer-grade memory modules are manufactured according to different production batches. And the ICs used in the manufacture are not fixed, which often causes serious compatibility and quality stability problems. Industrial control product verification and introduction takes a long time. Industrial memory module can provide long-term stable supply and fixed component guarantee (Fixed B.O.M.).

Effectively reducing the time and labor cost of repeated verification.

Unlike consumer products, which often take cost performance as the primary consideration.

Industrial products have extremely high requirements for quality, reliability and stability from material selection, production, testing to quality control.

WHY CHOOSE DELLWA?

From Dellwa sales manager Alan Tsai said:

“The application field of industrial memory module and commercial memory module are about automotive, telecom, GPS, embedded, recorder and displays, medical and healthcare, etc.

We are glad to provide you memory modules for suitable you are significant and sophisticated equipment. “

For more information about memory news, please click here.