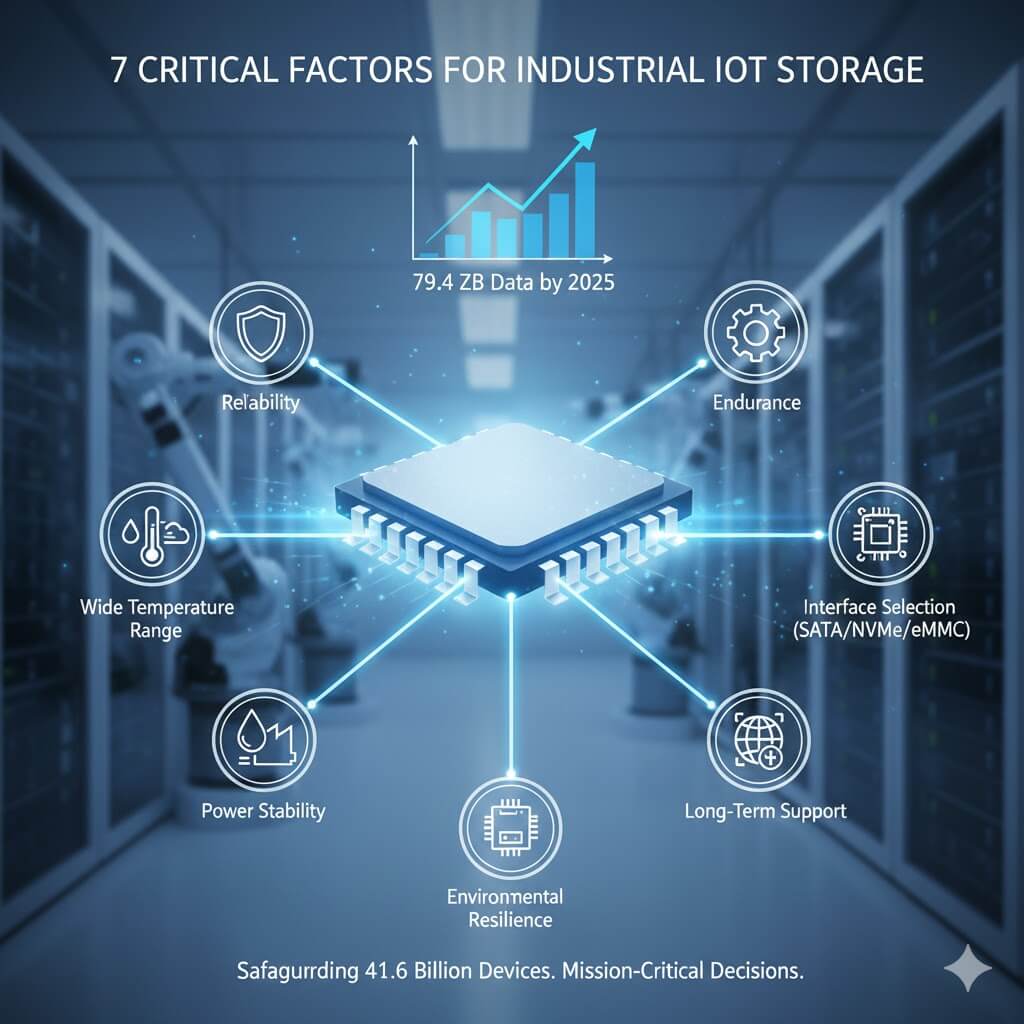

By 2025, over 41.6 billion IoT devices will generate 79.4 zettabytes of data globally—making storage reliability a mission-critical decision. The exponential rise in IoT device deployments, particularly in critical sectors like manufacturing, transportation, and infrastructure, underscores the urgent need for dependable storage. Storage failures in these environments do not just result in data loss; they cause costly downtime, compromise operational safety, and erode public trust. This article details the 7 critical factors that differentiate industrial-grade from consumer storage, offering a comprehensive guide to selecting the right Industrial SSD for your demanding IoT applications.

Factor 1 – Operating Temperature Range: Wide-Temp Requirements for IoT Device

Why Standard Storage Fails in Industrial IoT Device Environments

Most consumer-grade storage solutions are designed to operate within a narrow temperature range, typically between 0℃ and 70℃. However, industrial IoT devices often function in harsh environments where temperatures can fluctuate significantly, from sub-zero cold to extreme heat. Standard storage devices may experience data corruption, reduced lifespan, or complete failure under these conditions, jeopardizing mission-critical operations.

MIL-STD-810 Testing and Certification Standards

To ensure reliability, industrial-grade storage solutions are tested according to MIL-STD-810 standards, which evaluate performance under extreme temperature cycles, humidity, vibration, and shock. These certifications guarantee that the storage device can withstand the environmental stresses typical of manufacturing floors, transportation systems, and infrastructure monitoring, making them suitable for demanding IoT applications.

Factor 2 – Power Loss Protection (PLP): Safeguarding IoT Device Data Integrity

How Power Failures Destroy IoT Device Data

Unexpected power outages are common in industrial settings and can lead to data corruption or loss if the storage device lacks proper safeguards. Without power loss protection, ongoing write operations may be interrupted, resulting in incomplete data or filesystem corruption, which can cause costly downtime and data recovery efforts.

Capacitor-Based vs. Battery-Backed PLP Technologies

Industrial SSDs employ different PLP technologies to mitigate these risks. Capacitor-based PLP uses supercapacitors to provide short-term power during outages, ensuring data is safely written to non-volatile memory. Battery-backed solutions, though more complex, offer extended protection but add maintenance considerations. Selecting the appropriate PLP technology depends on the criticality of data integrity and operational environment.

Factor 3 – NAND Flash Type: SLC vs MLC vs TLC for IoT Device Endurance

Understanding NAND Flash Endurance Ratings

The type of NAND flash memory significantly impacts the durability and lifespan of an industrial storage solution. Endurance is measured by the number of Program/Erase (P/E) cycles a cell can reliably withstand.

Table 1: NAND Flash Type Comparison and IoT Application Recommendations

| NAND Type | Bits per Cell | P/E Cycles (Endurance) | Key Advantage | Optimal IoT Application Scenario |

| SLC (Single-Level Cell) | 1 | Highest (Approx. 60K-100K) | Extreme Endurance, High Speed | Critical Data Logging, High-Frequency Write Monitoring |

| MLC (Multi-Level Cell) | 2 | Medium (Approx. 3K) | Balances Cost and Endurance | Mixed Read/Write Workloads, Light Industrial Use |

| TLC (Triple-Level Cell) | 3 | Lowest (Approx. 500-1K) | Lowest Cost | Read-Intensive Applications, Non-Critical Data Storage |

| pSLC (Pseudo SLC) | 1 (Simulated) | High (Up to 20K) | Cost-Effective Industrial Solution | Industrial IoT requiring high endurance on a limited budget |

Cost-Performance Trade-offs for Different IoT Device Applications

The selection process is an essential trade-off between budget and operational needs. For mission-critical IoT devices that generate frequent and continuous data writes (e.g., condition monitoring sensors), SLC or industrial-grade pSLC SSDs are highly recommended to maximize lifespan. Conversely, for less demanding, read-heavy applications like simple remote infrastructure monitoring, TLC-based storage may suffice, offering substantial cost savings without compromising essential performance requirements.

Factor 4 – Interface Selection: SATA, NVMe, or eMMC for Your IoT Device

SATA III: Legacy Compatibility and Proven Reliability

The SATA III interface is widely used across the industrial landscape due to its extensive compatibility with existing systems and its proven, rock-solid reliability. Offering speeds up to 6 Gb/s, SATA is perfectly suitable for stationary IoT devices or legacy equipment where high throughput is not the critical bottleneck, and integration simplicity is valued.

NVMe: High-Performance Solution for Edge Computing IoT Device

eMMC: Compact Storage for Space-Constrained IoT Device

Embedded MultiMediaCard (eMMC) offers a compact, cost-effective, and highly integrated storage solution. As a small BGA package soldered directly onto the mainboard, eMMC is the preferred choice for space-constrained IoT devices, such as compact sensors, handheld industrial scanners, or low-power embedded controllers, where physical size and minimal power consumption are critical design considerations.

Factor 5 – Shock and Vibration Resistance: Durability for Mobile IoT Device

IEC 60068 Standards for Shock and Vibration Testing

Real-World Failure Scenarios in Transportation IoT Device

IoT devices used in transportation—including railway control units, fleet management sensors, or autonomous vehicle systems—are exposed to constant, punishing mechanical stresses. Standard storage would quickly fail under such continuous stress, leading to system failure and data loss. Industrial-grade storage solutions with high shock and G-force resistance (e.g., rated for 1,500G shock and 20G vibration) ensure continuous operation and data integrity under these perpetually dynamic conditions.

Factor 6 – Supply Chain Stability: Fixed BOM and Lifecycle Management

Why Fixed Bill of Materials (BOM) Matters for IoT Device Manufacturers

For manufacturers engaged in long-term, high-volume production of IoT devices, stability is paramount. A Fixed Bill of Materials (BOM) guarantees that all components within the SSD remain consistent over the product’s entire lifespan. This consistency simplifies initial manufacturing validation, subsequent quality control, and long-term maintenance. Crucially, a fixed BOM significantly reduces the risk of obsolescence and compatibility issues, which are critical in long-term IoT deployments often lasting 5 to 10 years.

Navigating Minimum Order Quantities (MOQ) and Lead Times

End-of-Life (EOL) Management and Migration Strategies

Factor 7 – Security Features: Encryption and Firmware Protection for IoT Device

AES-256 Hardware Encryption for Data-at-Rest Protection

Security is paramount for IoT devices transmitting or storing sensitive data. Industrial SSDs equipped with AES-256 hardware encryption provide the highest level of protection for data stored on the device (data-at-rest). This hardware-level encryption safeguards the data, making it inaccessible to unauthorized users even if the device is physically compromised or stolen.

Secure Firmware Updates and Tamper Detection

Beyond data encryption, the integrity of the drive’s operating system is crucial. Robust security features must include secure firmware update mechanisms that validate the authenticity of new firmware before installation, preventing malicious injection of harmful code. Furthermore, features like tamper detection and cryptographic hashing ensure the storage device maintains its integrity throughout its often long and unattended operational lifecycle.

Comparative Analysis: Evaluating Industrial SSD Suppliers for IoT Device Projects

Creating Your IoT Device Storage Requirements Matrix

Developing a comprehensive requirements matrix is the best practice for successful sourcing. This matrix should systematically compare suppliers based not only on price but also on technical specifications, environmental resilience certifications (MIL-STD-810, IEC 60068), security features, and support services. This rigorous approach ensures the chosen industrial storage aligns perfectly with long-term project needs.

Table 2: Industrial SSD Supplier Evaluation Matrix (Example)

| Evaluation Factor | Key Metric | Procurement Consideration |

| Environmental Resilience | Wide Temperature Range (±°C), MIL-STD Certification | Ensure compliance with extreme operating environments |

| Endurance | DWPD, NAND Type (SLC, pSLC) | Meet required data writing frequency (TBW) demands |

| Power Stability | PLP Type (Capacitor/Battery) | Prevent data corruption from unexpected power loss |

| Supply Chain Stability | Fixed BOM Commitment, EOL Policy | Ensure compatibility and maintenance for long-term deployment |

| Security Features | AES-256 Hardware Encryption, Firmware Protection | Protect data from physical and cyber threats |

Total Cost of Ownership (TCO) Analysis Beyond Unit Price

While initial purchase price is important, a Total Cost of Ownership (TCO) analysis provides a far more accurate picture of the long-term investment value. TCO must factor in costs associated with potential maintenance, guaranteed lifecycle support, power consumption over years of operation, and, most importantly, the financial cost of potential downtime caused by component failure. Investing in a high-quality, certified industrial SSD minimizes these hidden costs, delivering superior value over the lifespan of the IoT device.

Frequently Asked Questions (FAQ) – Industrial SSD for IoT Device

Q1: How do I choose between SLC, MLC, and TLC NAND for my IoT device application?

Match NAND type to your write intensity: SLC (60K-100K P/E cycles) for high-frequency data logging and critical monitoring systems; pSLC (up to 20K cycles) for industrial applications needing endurance on budget; MLC (3K cycles) for mixed read/write workloads; TLC (500-1K cycles) for read-intensive, non-critical applications. Calculate your daily writes—if exceeding 50GB/day continuously, invest in SLC or pSLC solutions to avoid premature failures.

Q2: Why does my IoT device need power loss protection (PLP) in the SSD?

Unexpected power failures in industrial settings cause data corruption and filesystem damage without PLP. Capacitor-based protection provides backup power (typically 40-250 milliseconds) to safely flush volatile DRAM buffers to NAND flash during outages—preventing data loss in remote deployments with unstable power grids. This feature is essential for SCADA systems, fleet management, and any application where data integrity directly impacts operational safety or regulatory compliance.

Q3: Should I choose SATA, NVMe, or eMMC interface for my industrial IoT device storage?

SATA III (6Gb/s, 550MB/s real-world) suits most data logging and monitoring systems with proven reliability and lower cost. NVMe (3.5GB/s via PCIe) is essential for edge computing applications performing AI inference or real-time video analytics requiring ultra-low latency (<100μs). eMMC offers compact BGA packaging for space-constrained designs like sensors and embedded controllers, though limited to 400MB/s and smaller capacities (typically ≤256GB).

Q4: How long will an industrial SSD last in continuous 24/7 IoT device operation?

Lifespan depends on NAND type and write workload: SLC drives typically last 5-10 years in continuous operation; pSLC 4-7 years; MLC/TLC 3-5 years. Always verify TBW (Total Bytes Written) rating against your daily write volume. Example: 256GB drive with 500 TBW supports approximately 274GB daily writes for 5 years. High-frequency data logging applications require higher endurance ratings to avoid premature storage failures.

Contact Dellwa today to upgrade your IoT device infrastructure with certified Industrial SSDs,

featuring guaranteed Fixed BOM and crucial Power Loss Protection (PLP).